Top 5 BEST Budget 3D Printers in 2025

I tested more than 50 of the best 3D printers for modeling, miniatures, crafting, prototyping, and more

I tested more than fifty of the top 3D printers firsthand. whether you’re a novice, a seasoned craftsman, or someone wishing to prototype your most recent product concept.

In addition to this compilation, I’ve included my top picks for the best hobby and small 3D printers based on my thorough testing and evaluation process.

Let’s get right to the point. Whether you’re working on personal projects or require a tiny, basic device for corporate use, the Bambu Lab A1 is, in my opinion, the greatest 3D printer for the majority of people.

From basic setup and calibration to testing all the features and determining material compatibility, from liquid resin machines to FDM, my tests at my 3D printer workshop are made to cover everything. See my in-depth evaluations of the top 3D printers in our guide below, since I have personally tested each one.

Table of Contents

BEST OVERALL

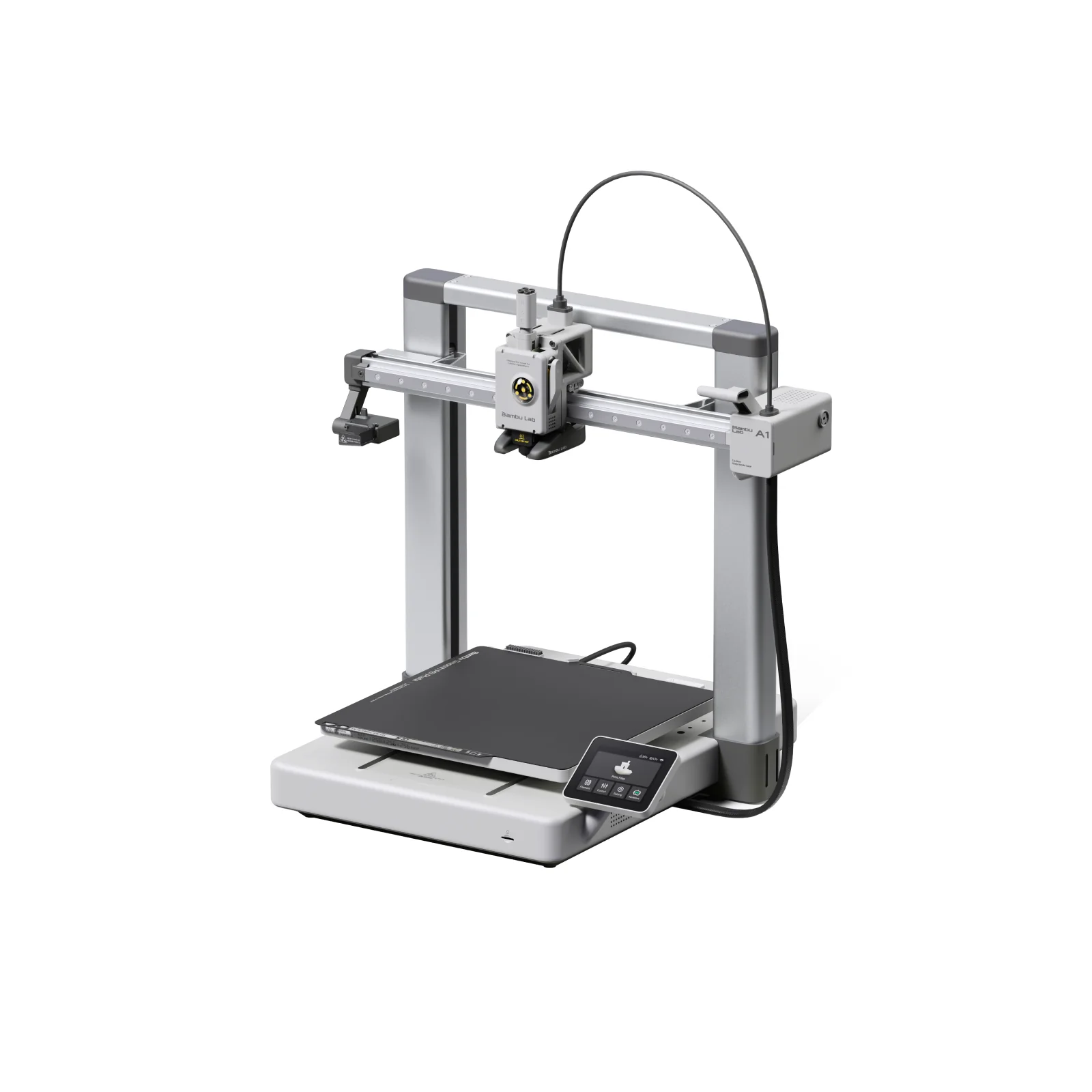

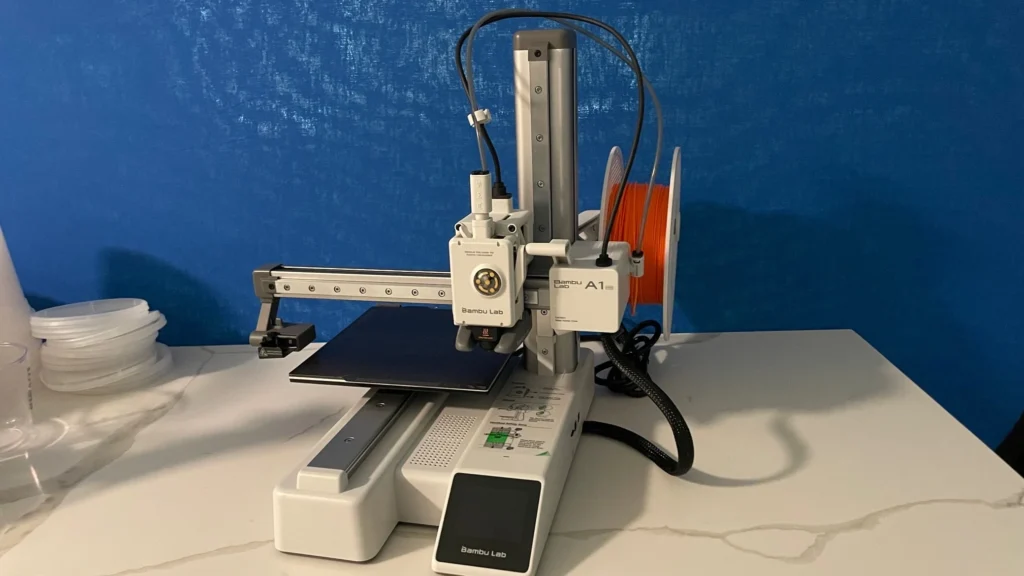

1. Bambu Lab A1

BEST ON A BUDGET

2. Creality Ender-3 V SE

BEST FOR BEGINNERS

3. Anycubic Kobra 3 Combo

BEST FOR EDUCATION

4. Creality K1C

BEST FOR BUSINESS

5. Original Prusa MK4S

1. Bambu Lab A1

After testing all of the most recent mainstream 3D printers, I believe the Bambu Lab A1 has the broadest appeal. Although it can be easily packed away with the AMS lite, its open frame design is relatively small and will fit on a desktop right away, which makes it a great choice over some of the larger, fully enclosed designs.

When I looked through the feature set, I noticed that it also directly compares with more expensive models, especially when it comes to speed and print quality.Additionally, it makes use of the Automatic Material System Lite (AMS Lite), which allows prints to use up to four colors simultaneously.

The A1 basically simplifies sophisticated 3D printing and has all the features I’ve come to anticipate from mid- to high-end machines, like a direct-drive extruder, pressure enhanced technology, and a tool head acceleration speed of 10,000 mm/s. That being said, the technology has been tried and proven, and the A1 is a highly sophisticated 3D printer with extensive material compatibility, standard auto bed leveling, and filament run-out sensors.

2. Creality Ender-3 V3 SE

Another Cartesian printer that has benefited from the manufacturer’s shift to quick CoreXY designs is the Creality Ender-3 V3 SE 3D Printer. This low-cost entry-level bed slinger now has all the sophisticated capabilities of the previous version, including auto bed leveling.

A few things might be lacking, including a camera, filament run-out sensor, or touchscreen, which could be a turnoff for some. The filament run-out sensor is a requirement, but since this printer is part of the Creality product range, you may always add accessories as your budget permits.

All things considered, the Ender-3 V3 SE is the greatest low-cost 3D printer for individuals starting out in 3D printing or looking for an affordable yet capable device because of its outstanding value, simplicity of use, print quality, and dependability.

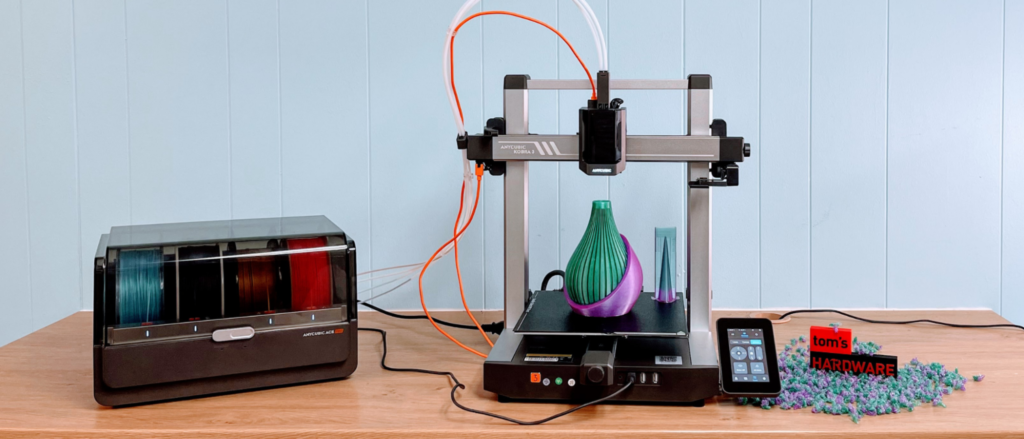

3. Anycubic Kobra 3 Combo

One of a new generation of reasonably priced, high-performing devices that I am witnessing is the Anycubic Kobra 3 Combo, a remarkable multifilament 3D printer. The robust metal frame has been developed to improve print quality and lessen vibrations, even though the design is similar to a conventional bed slinger.

Up to four filaments could be used simultaneously with the Anycubic Ace Pro multifilament box, which made the Combo version of the printer I reviewed an excellent option for both novices and those seeking a low-cost multifilament upgrade.Like other Kobra machines, the Kobra 3 is simple to use right away. I needed less than ten minutes to set up the machine so I could start printing. A significant upgrade over earlier AnyCubic designs, the redesigned interface and wide touchscreen monitor are simple to use. There are numerous advanced print capabilities, including an automatic bed leveling mechanism and auto filament run-out, as I would anticipate.

The Kobra 3 Combo has certain disadvantages in spite of its many advantages. the slower speed of multifilament printing in comparison to single-filament models, as well as the absence of an excess filament tray, which is typical of this design.Furthermore, this printer’s open frame design restricts its applicability in some settings, such classrooms, and when printing sophisticated materials.

All things considered, the Anycubic Kobra 3 Combo is the greatest multifilament 3D printer for novices because to its exceptional performance and pricing.

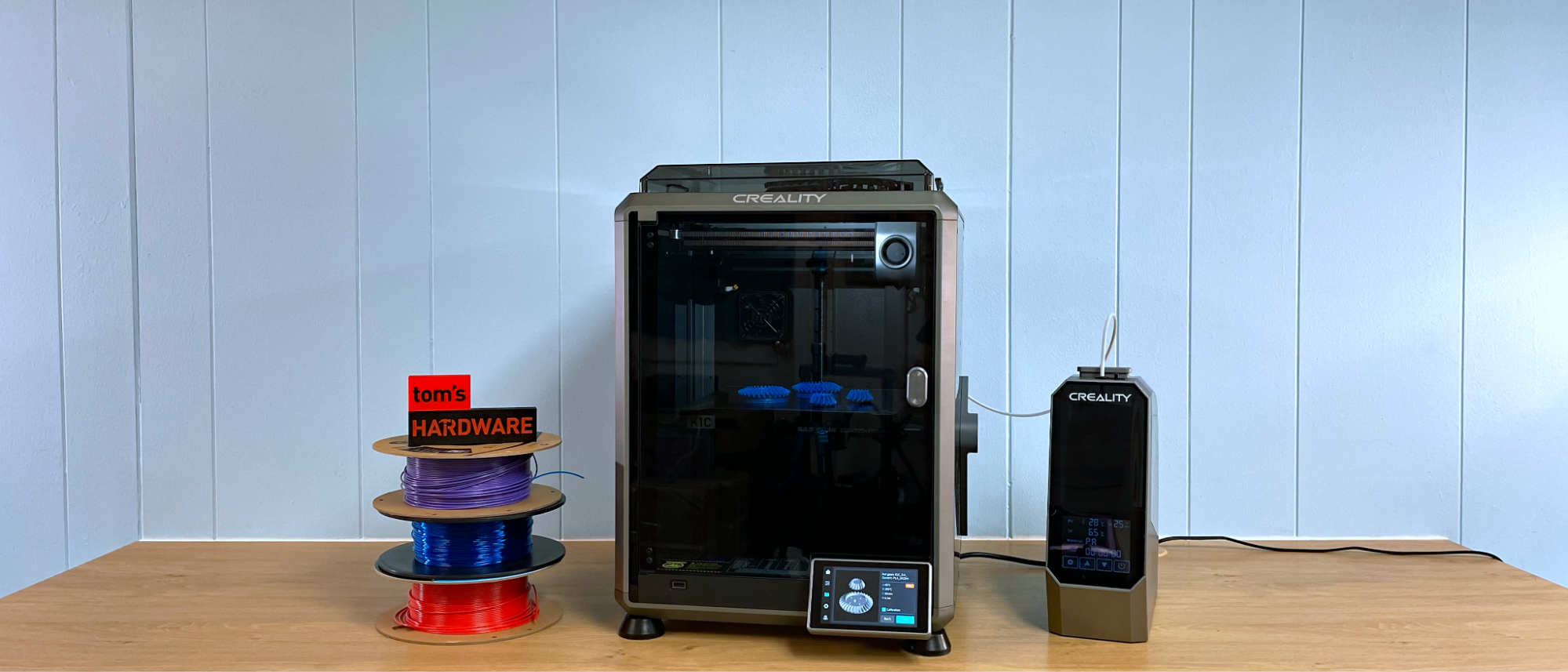

4. Creality K1C

The newest model in Creality’s fully enclosed K 3D printer range is the K1C. With a premium, sturdy frame and a tinted translucent part-glass shell that maintains the inner chamber warm for specialized materials, the machine’s design once again echoes the rest of the series.

With a few extra features over the K1 and K1 Max, the K1C enhances its capabilities. Some of the more sophisticated capabilities, like the AI camera, have trickled down from the larger machine, even though the K1 and K1C are nearly identical in terms of size and mechanical specifications.

It’s interesting to note that Creality has totally redesigned the tool head with a 300° hotend and a hardened steel nozzle tip that can handle specialized materials like carbon fiber. This improvement, which is reminiscent of the old Cel-Robox Dual with its specialized carbon heads from a few years ago, makes the machine much more appealing to individuals in the industry who use 3D printers.

It is difficult to see why someone would now choose the older K1 over this brand-new, ostensibly far more capable machine, even though the K1C isn’t a replacement for the K1. We were impressed by the K1 and K1 Max, two of the best 3D printers we have examined. Since the new machine’s fundamental mechanics are essentially the same, the integration of the AI camera and the new tool head will determine whether or not the quality has increased.

The hands-free auto-leveling system, flexible PEI construction plate, and fully enclosed design make setup and operation simple—exactly what you need in a classroom. The embedded AI camera, which offers failure detection, timelapse recording, and real-time print monitoring, improves reliability.

I’ve discovered that the K1C has a few little disadvantages in spite of its many advantages. It doesn’t support multifilament, so you’ll need to upgrade to the Creality K2 Plus for that function, and the fast speeds may have a minor impact on print quality.

5. Original Prusa MK4S

With numerous updates that restored its superior speed and performance, the Original Prusa MK4S 3D printer is what the MK4 should have been. Although the MK4 was good, other manufacturers’ machines began to catch up and match its performance; however, this all changed with the MK4S. I have discovered that this printer is an excellent option for both businesses and those of us who are ardent 3D print enthusiasts like myself.

The MK4S is a very popular choice for print farms because it is practically ready to use right out of the box, requires little setup, and offers high-speed printing with excellent reliability and minimal maintenance. Its automatic bed leveling and first-layer calibration make it simple to achieve perfect prints every time. Although the MK4S is more expensive, its versatility and the quality of its outputs make it worth the investment. If you would rather have a multi-filament 3D printer for business use, check out our Original Prusa XL review.

Additionally, the MK4S has a built-in NFC chip for Wi-Fi, which makes connecting easier and more seamless. The printer’s architecture still uses the traditional PRUSA design, but it incorporates new materials and manufacturing processes, such as an injection-molded LCD cover and PC blends with carbon fiber for some 3D-printed components. Therefore, the printer is getting more sophisticated even if it still has the characteristic maker style.

Manufacturers are allowed to create their own accessories and improvements thanks to a new optional GPIO board. Additionally, an accelerometer can be included, albeit customers’ needs for this will be quite specific. Despite their seeming slightness, the MK4S’s improvements over the MK4 greatly boost speed and performance.

What is a 3D printer?

In contrast to office-style printers, which print ink onto paper, 3D printers allow you to create digital models of real-world objects made of plastic, metal, and wood for prototyping, spare parts, or straight-to-market products. FDM printers are available in a wide range of sizes and shapes, and they are ideal for prototyping and creating larger objects. Resin-based (SLA, MSLA, and DLP) printers, on the other hand, allow for much greater detail, usually on a smaller scale, which makes them an excellent investment for anyone wishing to design jewelry or make tabletop miniatures.

3D printing is a means to create tangible items that is unlike any other approach we have seen, whether you are a hobbyist trying to get started in the field or your business depends on it. 3D printing is a simple method of producing goods using additive processes, which results in little to no waste. Additionally, the boundaries are almost unlimited because you can theoretically 3D print just about anything.

What kind of materials does a 3D printer use to print?

3D printers utilize a range of materials to print.

Because they are typically inexpensive and simple to use, entry-level FFF 3D printers continue to be the most popular. These filament printers, which use polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), PETG, TPU, nylon, and polycarbonate, are good for prototype and general use. Currently, PLA and ABS are the most widely used of these.

For complex modeling, a resin 3D printer or stereolithography (SLA) printer provides greater quality and accuracy, but they are more expensive. The final model is produced by these printers using a photosensitive resin that is exposed layer by layer.

What’s the difference between FFF vs FDM 3D printers?

Fused filament fabrication (FFF) and fused deposition modeling (FDM) 3D printers use the same printing process and materials, but they differ in a few ways. First, FDM is a trademark of Stratasys, though other companies may use it. However, this is not the only difference; genuine industrial-grade FDM printers use more materials than FFF 3D printers and offer larger build platforms, fusing use layers closer together for a stronger bond. However, this makes them more costly to purchase and operate than FFF printers, which are more common among novices.

Do 3D printers consume a lot of power?

The size of your 3D printer, the materials you use, and the length of time you spend using it all affect this. When compared to other 3D printers, FDM printers, in our experience, consume the least amount of power.

What is the most lucrative thing to make with a 3D printer?

There are many lucrative products that can be produced using a 3D printer, including teaching aids, replacement parts, prototypes, and personalized items like phone cases and more. If properly marketed, any of those products has the potential to be profitable.

Is it worthwhile to invest in 3D printing?

Like most things, it depends on how and how often you plan to use your 3D printer. 3D printing is well worth the investment if you enjoy modeling and printing, whether for personal or professional use. This is especially true as the price of entry-level 3D printers continues to decline.

When choosing a 3D printer, you should think about what you plan to use it for. A small-size printer is appropriate for printing small items, but a large printer is obviously the best choice for larger creations. A high resolution printer is required for printing high-quality objects with fine details, but these prints will cost more and require more preparation time.

Once the sales are live, keep an eye out for Prime Day and Black Friday 3D printer deals for even more savings. Other factors to consider include the printer’s interface and general ease of use, as well as the type of software it uses, the type of filament, the build platform, and the price.

From the best business card printing services to the best home and office printers, we have tested, evaluated, and rated a wide range of printing equipment, services, and tools. We use the same exacting testing procedure on each product whether we’re analyzing and contrasting the top 3D printing devices or all-in-one printers so you can make an informed decision.

Our evaluation of the top 3D printers employs a set of custom standards that assist highlight each model’s advantages and disadvantages so that they can eventually be contrasted with those of other products. A filament printer will be evaluated for stringing, bridging, and speed, along with other information on detail, quality, and noise levels. These will vary based on the type of printer.

Every 3D printer in our 3D print workshop goes through a thorough testing process, regardless of how budget-friendly or outrageously expensive it is; our testing procedures are designed to put these printers through rigorous evaluations to ensure we identify the best options available for you. The testing journey begins with the initial build, set-up, and calibration, assessing the ease of the process. While some printers can be up and running within minutes, others may require far more time and effort. This will be done fairly, with dues given to different materials and printer types, with resin printers being subject to smaller, more detailed models to replace the stringing test.

We then look at the bridging, overhangs, stringing, layer adhesion, surface finish, dimensional correctness, and first layer print quality. As we examine how long it takes the printer to create a model without sacrificing print quality, speed is still another crucial consideration. Noise levels should also be taken into account. Some printers are very noisy, especially when the speed increases. This is fine for quick prints but very annoying for prints that take hours or days to complete.

functionality including software compatibility, user interface usability, connectivity options, and any extra functionality provided are all carefully examined as part of our extensive testing. We investigate material compatibility and evaluate the printer’s adaptability by testing it with different resins or filaments.

After putting each printer through these tests and evaluations, we can confidently give you an informed recommendation as to which is the best 3D printer. Lastly, we take into account the price of the printer’s overall performance and features, making sure it matches our expectations; we carefully evaluate the printer’s intended market, taking into account specific user needs and suitability for various applications; and we analyze the design and aesthetics, acknowledging the importance of a well-designed and aesthetically appealing product.